QA Consultants: Future-proofing our company

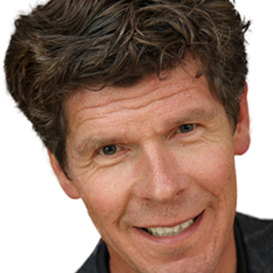

QA Consultants is a Canadian technology success story and a case study of how to disrupt a static industry. Initially, the company provided testing resources for companies looking to outsource their testing requirements. By prioritising innovation strategies focused on dramatically improving client value and internal efficiencies, and spending millions on R&D to develop new testing methodologies, automation and internal processes, QA Consultants has today become a dynamic and rapidly growing IT services organisation, and North America’s largest dedicated software quality assurance and testing company. Peter Watkins, Chief Operating Officer, explains some of the key factors that have led to this company’s success and the role played in its development by the National Research Council of Canada Industrial Research Assistance Program (NRC IRAP) and ITEA, among others.

Going local

Founded by Alex Rodov in 1994, QA Consultants has been in business for some 26 years, beginning as a subcontractor to the major players like Accenture and Deloitte before deciding to go directly to the industry, initially through staff augmentation. “When I came on board, about eight years ago,” Peter recalls, “we looked at the offshore market and made some fundamental strategic choices, one of which was to be local. This meant our clients would have direct access to our resources, whether in Canada or beyond. To be able to compete with Asian price points, we had to create a different model. And NRC IRAP helped us many years ago to find a way of improving the efficiency of our testing methodologies such that we could compete with offshore prices. This resulted in something called the TestFactoryTM . In essence, our TestFactoryTM enabled us to bridge the 30% inefficiency gap between development and testing. Not only were we able to get our price below that of offshore competition but we were also able to generate the benefits of being local. That was a great differentiator in building our business. In fact, NRC IRAP has always been enormously supportive of our research right through to the present and has been a key contributor to our success.

Criticality of software innovation

“As we applied more science, innovation and technology, the testing industry began to change quite dramatically. We’ve gone from manual testing to automation testing – we’re using the latest science of advanced model-driven based testing. Our engineers are Masters and PhDs. We’re building digital twins of factory robots and vehicles to do testing in a fully simulated environment. In short, the science of testing has helped us transform our business.” He goes on. “It stands to reason, therefore, that software innovation is critical to our business. We build systems to test systems and that requires systems engineers we hire, train and deploy. The industry is advancing rapidly and so we are grateful for our involvement in ITEA, and to NRC IRAP which was instrumental in bringing us together.” As Canada’s National Office for Eureka, NRC IRAP not only facilitated the connection to ITEA but also provided valuable support early on through various partnering development activities that introduced QA Consultants to potential collaboration opportunities beyond Canada’s borders. They also provided specialised advisory services through the NRC IRAP Industrial Technology Advisor, who supported them throughout their international collaboration journey, from coinnovation partner selection to project proposal development and execution.

The ITEA business boost

“What we have found is that North America is behind the curve relative to the advanced testing science being applied in Europe. As part of the ITEA initiative, we were introduced to Dr Holger Schlingloff, who is Chief Scientist of the System Quality Center (SQC) at the Fraunhofer Institute FOKUS and professor for software engineering at the Humboldt University of Berlin. In addition to working with us on the XIVT project, he came over to train our automation team on advanced model-based design and testing methods. This training enabled us to create huge efficiencies and has become transformational for our business. I’d go so far as to say that our involvement in ITEA has created a kind of future-proofing for our company in many ways. In the XIVT project, we are taking a methodological approach with a focus on the automotive sector. Ecosystems involving the Internet of Things have created an exponential number of configurations to be tested often in the millions. This testing complexity has a major negative impact on industry’s ability to adequately test and release products in a timely manner. Apart from leading the Canadian consortium, one of the methodologies for variant testing we have already produced is called BeVAR, not to be confused with Bieber,” Peter jokes, “and this is helping to give an efficiency boost that pays off in terms of real economic value that we are applying to our 'other' client projects such as testing Guidewire or SAP implementations, or testing complex digital transformation initiatives in retail and financial services.”

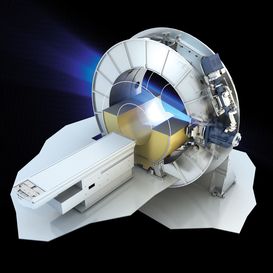

XIVT

The XIVT project runs from 2018 to 2022 and aims to define a method and toolchain for testing highly configurable, variant-rich embedded systems in the automotive, rail, telecommunication and industrial production domains. The method is founded on a knowledge-based analysis of requirements formulated in natural language, and a modelbased test generation at product-line level. By generating a highly effective, cost-efficient quality assurance, the shift to autonomous, flexible and adaptive applications is enhanced and results in higher test coverage, more flexible processes of higher quality and better products.

A diverse and collaborative network

“Much of the communication during the project has been virtual so COVID-19 has not dramatically impacted our effectiveness. We do miss the face-to-face contact. When we actually come together, we do get a lot done. The after-work comradery also helps with building trust,” Peter says with a smile. “But the project is nevertheless progressing extremely well. And what is an enormous plus for our involvement is the array of cross-cultural differences. People approach and deal with situations differently. We learn so much from our XIVT colleagues who are, quite literally, the smartest in the world at what they do. ITEA enables an enormously important network. By the way, QA Consultants was set to sponsor a World Productivity Congress on Advanced Manufacturing on Industry 4.0 in Bangalore in May this year. Through our ITEA network connections we were able to invite prominent leaders such as Zeynep Sarılar, Chairwoman of ITEA, and Holger Schlingloff, Chief Scientist at Fraunhofer FOKUS, to be keynote speakers. They accepted but due to COVID-19, the event had to be rescheduled to 2022. Their willingness really shows the spirit of collaboration and support there is in the ITEA Network.”

In conclusion, Peter notes that with the United States not being an ITEA participant, “the knowledge and lessons we’re getting and the new technologies that we’re building, several of which we’re looking to patent, as a result of our participation, give us a competitive edge and enhances the trust our clients have in our capabilities knowing we have earned the endorsement of ITEA and NRC IRAP in approaching the North American marketplace.”

More information

https://qaconsultants.com

Other articles

Use the arrows to view more articles

Editorial

By Jan Jonker

Country Focus: Canada

Connecting companies to enable access to new markets and global value chains

QA Consultants

Future-proofing our company

ITEA Success story: C³PO

C³PO democratises City Planning

Viewpoint on entrepreneurship

Innovare - to make new again

End user happiness: SoRTS and STARLIT

Tumour in sight during radio treatment

New ITEA Vice-chairman: Jean-François Lavignon

The new helmsman at the wheel

ITEA Success story: ACOSAR

An innovative simulation that saves time and money

SME in the spotlight: GΩHM

Embedded intelligence to improve quality of life

The Smart City Business Event

The Road to Smart City Live

State of the Art

A compass for your projects

Online ITEA PO Days

ITEA Community clearly showed its agility at the Online ITEA PO Days 2020